Continental C90 Parts Manual: A Comprehensive Guide

This manual details the Continental C90 engine, offering comprehensive parts information. It includes diagrams, identification guides, and compatibility charts for C-75, C-85, C-90, and O-200 models.

The Continental C90 engine represents a significant milestone in aviation power, renowned for its reliability and widespread use in various light aircraft. This parts manual serves as an essential resource for anyone involved in the maintenance, repair, or restoration of these engines. Understanding the C90’s design and components is crucial for ensuring safe and efficient operation.

This manual specifically covers the C90-16F, C-75, C-85, C-90, and O-200 models, providing detailed illustrations and part numbers to facilitate accurate identification and ordering. Whether you are a seasoned aviation mechanic or a dedicated homebuilder, this guide will prove invaluable. It’s designed to assist in navigating the complexities of the engine’s systems, from the fuel and ignition systems to the lubrication components.

Furthermore, the manual addresses the challenges of sourcing parts, including information on obsolete components and resources for finding additional support. The Continental Forum Bucharest is mentioned as a potential resource, offering accommodation and potentially related aviation connections.

Understanding the C90 Parts Manual

This Continental C90 Parts Manual is structured to provide a clear and concise reference for all engine components. It utilizes detailed diagrams, including top views of cylinder arrangements, and right/left front views for specific models like the C-90 and O-200. Each illustration is accompanied by corresponding part numbers, streamlining the identification process.

The manual’s organization allows users to quickly locate specific parts, whether searching by component name or utilizing the catalog information, such as X30011 ⏤ C90. It also highlights compatibility between different engine models – C-75, C-85, C-90, and O-200 – simplifying cross-referencing.

Pay close attention to sections detailing screw and drive specifications, as these are critical for proper assembly. Information regarding obsolete parts is also included, aiding in sourcing replacements. Remember to consult the manual’s visual references alongside the textual descriptions for optimal understanding.

Engine Components & Identification

This section focuses on identifying key engine parts, utilizing identification plates for models C90-16F and O-200. Diagrams illustrate component locations for easy reference.

Engine Identification Plates (C90-16F)

The Engine Identification Plate for the C90-16F model is crucial for accurate parts sourcing and maintenance. This plate contains vital information regarding the engine’s serial number, model designation, and potentially other specifications relevant to its production and configuration. Locating this plate is the first step in correctly identifying the engine and ensuring compatibility when ordering replacement parts.

Careful examination of the plate is necessary, as slight variations in numbers or letters can indicate different engine builds or modifications. The plate’s position on the engine block is standardized for the C90-16F, facilitating easy location during inspections or repair work. Referencing the parts manual alongside the plate’s information ensures accurate identification and prevents ordering incorrect components. Maintaining a clear record of the plate’s details is recommended for future reference and streamlined parts procurement. Proper identification avoids costly errors and ensures the longevity of the engine.

Engine Identification Plates (O-200)

The O-200 engine’s Identification Plate serves a similar, yet distinct, purpose to the C90-16F plate. It’s the primary source for determining the specific configuration of this engine model, vital for ordering the correct replacement parts. The plate details the engine’s serial number, model designation (O-200), and potentially other manufacturing specifics. Accurate interpretation of this information is paramount for successful maintenance and repair.

Unlike the C90-16F, the O-200 plate may have a slightly different layout or positioning on the engine block. Therefore, familiarizing oneself with the typical location of the O-200 plate is essential. Cross-referencing the plate’s data with the parts catalog ensures that all ordered components are fully compatible. Keeping a detailed record of the plate’s information is highly recommended for future servicing and parts requests. Correct identification prevents delays and ensures the engine operates reliably and efficiently.

Cylinder Arrangement Diagram (Top View)

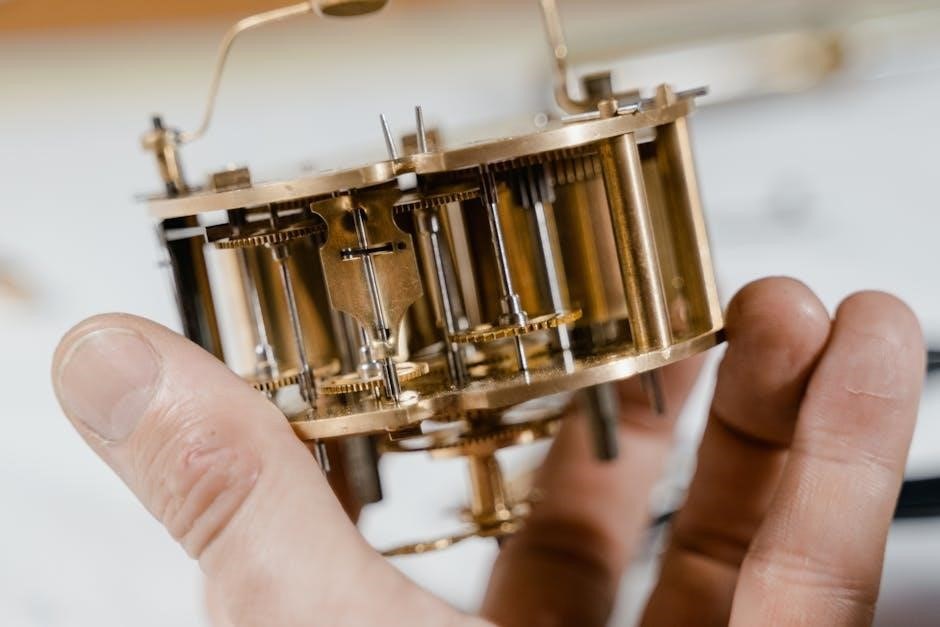

The Cylinder Arrangement Diagram, presented as a top view, is a crucial visual aid within the Continental C90 parts manual. This diagram clearly illustrates the physical layout of the engine’s cylinders, their numbering sequence, and the relative positioning of key components attached to each cylinder. Understanding this arrangement is fundamental for tasks like valve adjustments, spark plug replacement, and fuel injector servicing.

This diagram isn’t merely a static image; it’s a roadmap for disassembly and reassembly. It helps technicians visualize how parts interact and ensures correct installation. The diagram often includes labels identifying specific cylinders (e.g., #1, #2, etc.) and associated components. Referencing this diagram alongside the parts catalog allows for precise identification of parts related to each cylinder. Accurate interpretation minimizes errors and streamlines the maintenance process, contributing to optimal engine performance and longevity.

Major Engine Systems

This section details the Continental C90’s fuel, ignition, and lubrication systems. It provides detailed parts breakdowns and diagrams for each system’s components, aiding maintenance.

Fuel System Parts

The fuel system for the Continental C90 engine is meticulously detailed within this manual, ensuring accurate identification and replacement of components. This section covers a wide array of parts crucial for optimal engine performance. Key elements include the carburetor, responsible for mixing air and fuel, along with fuel lines, filters, and pumps designed to deliver a consistent fuel supply.

Detailed illustrations showcase each part, accompanied by specific part numbers for easy ordering. The manual also addresses fuel nozzles, fuel gauges, and related fittings. Troubleshooting guides are integrated to assist in diagnosing fuel system issues, such as fuel leaks or inconsistent engine operation. Compatibility information clarifies which parts are interchangeable between different C90 variants, streamlining the repair process. Proper maintenance of these components is vital for maintaining engine efficiency and preventing costly damage. This section empowers mechanics and enthusiasts alike with the knowledge to confidently service the C90’s fuel system.

Ignition System Parts

The Continental C90’s ignition system is thoroughly documented in this manual, providing a complete breakdown of its components. This section focuses on ensuring reliable spark delivery for consistent engine firing. Key parts covered include the magneto, responsible for generating the high-voltage spark, alongside spark plugs, ignition wires, and the associated hardware.

Detailed diagrams illustrate the precise arrangement of each component, with corresponding part numbers for accurate identification. The manual also details the distributor, points, and condenser – critical elements for timing and spark control. Troubleshooting guides assist in diagnosing ignition-related problems, such as weak spark or engine misfires. Compatibility charts clarify interchangeability between different C90 models. Maintaining a properly functioning ignition system is paramount for optimal engine performance and fuel efficiency. This section equips users with the necessary information to diagnose, repair, and maintain the C90’s ignition system effectively.

Lubrication System Parts

This section of the Continental C90 parts manual meticulously details the engine’s lubrication system, vital for minimizing friction and wear. It provides a comprehensive catalog of components, including the oil pump, responsible for circulating oil throughout the engine. Detailed illustrations showcase the oil pan, oil filter, and oil cooler, alongside their respective mounting hardware and seals.

The manual also covers oil lines, pressure gauges, and relief valves, crucial for maintaining optimal oil pressure and flow. Part numbers are clearly indicated for easy identification and ordering. Troubleshooting guides assist in diagnosing lubrication-related issues, such as low oil pressure or leaks. Proper lubrication is essential for extending engine life and preventing catastrophic failure. This section empowers users to effectively maintain and repair the C90’s lubrication system, ensuring reliable and long-lasting performance. Diagrams illustrate the system’s layout for clear understanding.

Detailed Component Breakdown

This section provides in-depth specifications for individual parts like screws and drives (X30011 ⏤ C90). It clarifies compatibility between C-75, C-85, C-90, and O-200 engines.

Screw, Drive Specifications

Detailed screw and drive specifications are crucial for proper Continental C90 engine maintenance and repair. This section of the parts manual meticulously outlines the various screw types used throughout the engine, including their size, thread pitch, material, and head style. Accurate identification is paramount, as using incorrect fasteners can lead to component failure or compromised structural integrity.

The manual provides specific data for drive screws, detailing their length, diameter, and drive type (e.g., Phillips, slotted, Torx). Illustrations accompany these specifications, aiding in visual confirmation. Furthermore, torque specifications are included, ensuring that fasteners are tightened to the correct tension, preventing over-tightening or loosening during operation.

Understanding these specifications is vital when sourcing replacement parts, particularly when dealing with obsolete or hard-to-find components. The manual serves as a definitive guide for mechanics and enthusiasts alike, guaranteeing accurate repairs and maintaining the reliability of the Continental C90 engine.

Parts Catalog Information (X30011 ౼ C90)

The X30011 parts catalog is a cornerstone resource for Continental C90 engine owners and mechanics. This comprehensive catalog, available in PDF format, contains 54 pages of meticulously detailed illustrations and part numbers. It’s specifically designed for the C-75, C-85, C-90, and O-200 engine families, offering a single point of reference for all component identification and ordering.

Each page features exploded diagrams showcasing the assembly of various engine systems, allowing for easy identification of individual parts. Part numbers are clearly labeled, facilitating accurate ordering from authorized Continental distributors. The catalog covers a wide range of components, from major assemblies like cylinder heads and crankshafts to smaller items like gaskets, seals, and hardware.

This catalog is invaluable for restoration projects, routine maintenance, and troubleshooting. Its detailed nature ensures that the correct parts are always sourced, contributing to the longevity and reliable performance of the Continental C90 engine.

C-75, C-85, C-90 & O-200 Compatibility

A significant benefit of the Continental C90 parts manual is its coverage of multiple engine models: the C-75, C-85, C-90, and O-200. While these engines share a common lineage and many core components, understanding their compatibility is crucial for accurate parts replacement and maintenance. The manual meticulously details which parts are interchangeable between these models, preventing incorrect installations and potential engine damage.

Often, components like screws, drive specifications, and certain gaskets can be utilized across multiple engine variants. However, critical differences exist in areas such as cylinder heads, pistons, and crankshafts, necessitating model-specific parts. The manual clearly outlines these distinctions, providing detailed charts and diagrams to aid in identification.

This cross-referencing capability streamlines the parts sourcing process, reducing the need to carry an extensive inventory and simplifying repairs for owners of these classic Continental engines.

Visual References & Diagrams

This section provides essential visual aids, including three-quarter rear views (C90-16F), front views (C-90 & O-200), and a top-view cylinder arrangement diagram for clarity.

Three-Quarter Right Rear View (C90-16F)

This detailed diagram presents a three-quarter right rear perspective of the Continental C90-16F engine. It’s a crucial visual reference for identifying component placement and understanding the engine’s overall configuration. The illustration meticulously showcases the arrangement of key parts, assisting in accurate assembly, disassembly, and maintenance procedures.

Users can utilize this view to pinpoint the location of various systems, including the fuel, ignition, and lubrication components. It’s particularly helpful when cross-referencing with the parts catalog (X30011 ⏤ C90) to ensure correct part identification and ordering. The clarity of the diagram allows for easy visualization of connections and relationships between different engine elements.

Furthermore, this perspective aids in troubleshooting and diagnosing potential issues. By visually comparing the engine to the diagram, technicians can quickly identify any misplaced or damaged parts. This visual guide is an invaluable tool for anyone working with the Continental C90-16F engine, promoting efficient and accurate repairs.

Right Front View (C-90)

The Right Front View illustration of the Continental C-90 engine provides a clear and comprehensive visual guide for technicians and enthusiasts. This detailed depiction is essential for understanding the engine’s front-facing components and their precise arrangement. It serves as a critical reference point during maintenance, repair, and overhaul procedures.

This perspective allows for easy identification of key parts, such as the starter, alternator, and various accessory brackets. Users can effectively cross-reference the diagram with the parts catalog (X30011 ⏤ C90) to confirm component locations and part numbers. The illustration’s clarity minimizes ambiguity and ensures accurate part selection.

Moreover, the Right Front View aids in diagnosing potential issues by providing a visual baseline for comparison. Technicians can quickly identify any discrepancies or damaged components. This visual resource is an indispensable tool for anyone working with the Continental C-90 engine, promoting efficient and reliable service.

Left Front View (O-200)

The Left Front View diagram of the Continental O-200 engine is a crucial visual aid for maintenance and repair. This detailed illustration showcases the engine’s components from the left side, offering a clear understanding of their positioning and interrelationships. It’s an invaluable resource for both experienced mechanics and those new to the O-200.

This perspective highlights key elements like the magneto, fuel pump, and associated plumbing. Technicians can utilize this view in conjunction with the parts catalog (X30011 ౼ C90, applicable to O-200 as well) to accurately identify and order replacement parts. The diagram’s precision minimizes errors during assembly and disassembly.

Furthermore, the Left Front View assists in troubleshooting by providing a visual reference for identifying potential problems; Comparing the diagram to the actual engine allows for quick detection of missing or damaged components. This detailed visual guide ensures efficient and accurate servicing of the Continental O-200 engine.

Manual Usage & Resources

This section provides guidance on utilizing the manual, including obsolete parts information and support resources. Explore the Continental Forum Bucharest for related assistance.

Obsolete Parts Information

Locating replacement parts for the Continental C90 engine can present challenges due to the age of the aircraft and engine models it powers. Many original parts have been declared obsolete by Continental, meaning they are no longer manufactured. This necessitates resourceful sourcing strategies for maintaining these engines.

Several avenues exist for acquiring obsolete parts. Salvage yards specializing in aircraft engines often stock used, serviceable components. Online marketplaces and aviation-specific forums can connect you with individuals or businesses possessing surplus inventory. However, careful inspection and verification of the part’s condition and airworthiness are crucial when purchasing from these sources.

Furthermore, exploring alternative manufacturing options, such as aftermarket suppliers or specialized machine shops capable of recreating discontinued parts, may be necessary. Documentation and adherence to approved data are paramount when utilizing non-original components. Maintaining detailed records of all parts sourced and installed is essential for continued airworthiness and regulatory compliance. Always prioritize safety and consult with a qualified aviation mechanic.

Continental Forum Bucharest (Related Information ౼ Hotel)

While seemingly unrelated to engine parts, the Continental Forum Bucharest offers convenient accommodation for aviation professionals or enthusiasts visiting the area for maintenance, training, or related events. The hotel, recently renovated and rebranded in June 2021, provides a 4-star experience with a vibrant atmosphere.

Located on Izvor Street, near Izvor Park and the metro station, the hotel boasts central access to Bucharest’s Old City Center, Union Square, and the Palace of Parliament. Guests benefit from potential discounts – a 20% reduction when booking directly – and the option to utilize holiday vouchers for payment.

Special packages cater to students and seniors, enhancing the hotel’s appeal. Contact information is readily available, and the location provides easy access to transportation. Though not directly involved with C90 parts, the Continental Forum Bucharest offers a comfortable base for those engaged in aviation-related activities in the region, providing a respite from the complexities of engine maintenance and parts sourcing.

Finding Additional Parts Support

Sourcing parts for the Continental C90 engine, particularly older models, can present challenges due to potential obsolescence. Beyond the primary parts catalog (X30011 ⏤ C90), several avenues exist for locating necessary components. Online aviation parts marketplaces and specialized engine rebuilders are valuable resources.

Due to the age of some C90 engines, identifying compatible parts from C-75, C-85, and O-200 models is often crucial, as indicated within the manual’s compatibility section. Thorough cross-referencing is essential. Investigating salvage yards specializing in aircraft engines may yield hard-to-find items.

Furthermore, connecting with aviation communities and forums can provide access to a network of experienced mechanics and parts suppliers. Be prepared to provide precise part numbers and engine specifications when requesting assistance. Understanding obsolete part information, as detailed in the manual, is vital for successful sourcing and potential alternatives.