The 4.5 HP Mercury outboard motor is a reliable, compact power solution for small boats. Its throttle linkage system ensures smooth engine operation and optimal performance control.

1.1 Overview of the Mercury 4.5 HP Outboard Motor

The Mercury 4.5 HP outboard motor is a compact, lightweight engine designed for small boats and inflatables. It offers excellent portability, fuel efficiency, and reliable performance. With a simple design, it is easy to operate and maintain, making it ideal for recreational boating. The motor features a manual start system and a tiller handle for precise control. Its compact size and lightweight construction allow for easy storage and transportation. The engine is built with durable materials to withstand marine conditions. This motor is a popular choice for anglers and boating enthusiasts seeking a dependable power source for smaller watercraft. Its compact design ensures minimal space usage while delivering sufficient power for smooth operation.

1.2 Importance of the Throttle Linkage System

The throttle linkage system is crucial for controlling the Mercury 4.5 HP outboard motor’s speed and performance. It connects the throttle lever to the engine, enabling precise control over fuel delivery and rpm. A well-functioning linkage ensures smooth acceleration, responsive handling, and optimal engine operation. Proper maintenance and adjustment of this system are essential to prevent issues like erratic engine behavior or loss of control, which could compromise safety and performance. The throttle linkage’s reliability directly impacts the motor’s efficiency, making it a key component for enjoyable and safe boating experiences.

Understanding the Throttle Linkage System

The throttle linkage system connects the throttle control to the engine, enabling precise speed and RPM control. It ensures smooth operation and responsive handling, essential for safe boating.

2;1 Components of the Throttle Linkage

The throttle linkage system comprises several key components, including the throttle lever, linkage rods, cables, and connectors. These parts work together to transmit control inputs from the throttle to the engine, enabling precise speed and RPM adjustments. The throttle lever is typically mounted on the boat’s control panel, while the linkage rods and cables connect it to the outboard motor. Proper alignment and tension of these components are essential for smooth operation. The system also includes adjustment points to fine-tune its responsiveness, ensuring optimal performance under various boating conditions. Regular maintenance of these components is critical to prevent wear and tear, which can lead to control issues.

2.2 How the Throttle Linkage Operates

Operation begins with the throttle lever, which, when moved, activates the linkage rods and cables. These components adjust the engine’s throttle plate, controlling airflow and, consequently, fuel injection and engine speed. The system relies on precise alignment and smooth movement to ensure accurate control. Proper synchronization of these elements is crucial for achieving seamless acceleration and deceleration. Any misalignment or friction within the linkage can result in less responsive or inconsistent engine performance. Regular maintenance is essential to uphold the system’s efficiency and responsiveness, ensuring optimal boating experiences.

The Throttle Linkage Diagram

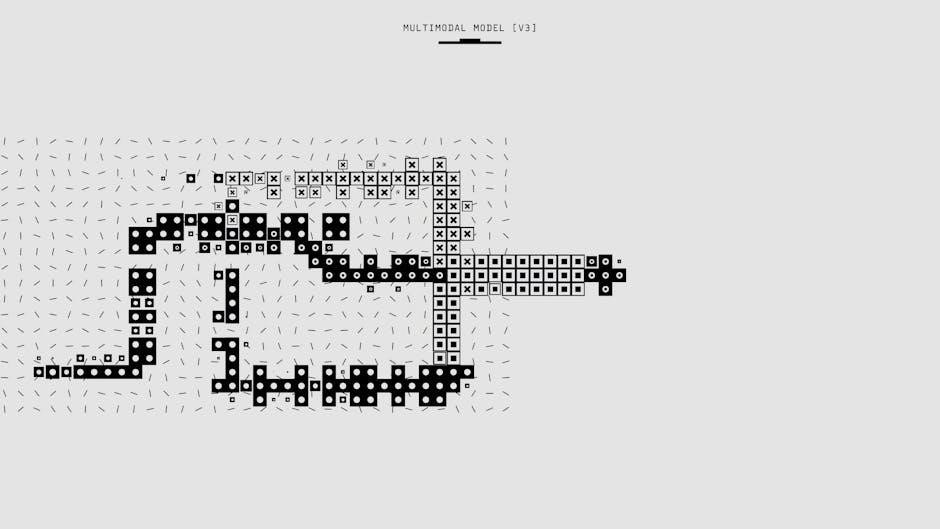

The throttle linkage diagram provides a clear, detailed visual guide to the system’s components and connections, essential for understanding and maintaining the outboard motor’s operation.

3.1 Key Features of the Diagram

The diagram highlights the throttle linkage system’s components, including the throttle lever, cables, and connecting rods. It showcases the motor’s gearcase and propeller alignment, ensuring proper throttle operation. The layout provides clear labels for each part, such as the idle adjustment screw and the shift mechanism. Color-coded lines differentiate between the throttle and shift cables, simplifying troubleshooting. The diagram also includes reference numbers for easy identification of components, making it a valuable resource for maintenance and repairs. Its detailed structure allows users to visualize how the throttle linkage integrates with the outboard motor’s overall functionality, ensuring precise control and optimal performance.

3.2 How to Read the Diagram Effectively

To interpret the throttle linkage diagram accurately, start by identifying key components such as the throttle lever, cables, and connection points. Use the color-coded lines to distinguish between throttle and shift mechanisms. Locate reference numbers or labels to cross-reference with the parts list. Begin with the motor’s gearcase and trace the linkage to the throttle lever, ensuring alignment and proper connections. Pay attention to arrows indicating the direction of movement or force. Use the diagram’s legend or key to understand symbols and abbreviations. By systematically analyzing each section, users can ensure accurate repairs, adjustments, and maintenance of the 4.5 HP Mercury outboard motor.

Maintenance and Adjustment of the Throttle Linkage

Regular maintenance ensures smooth operation and longevity of the throttle linkage. Adjustments optimize performance and prevent mechanical issues, ensuring reliable and safe boating experiences.

4.1 Regular Maintenance Tasks

Regular maintenance of the throttle linkage involves inspecting for wear, cleaning corrosion, and lubricating moving parts. Check cables for fraying or damage and ensure all connections are secure. Adjust linkage alignment to prevent binding or misalignment. Lubricate pivot points and hinges to maintain smooth operation. Inspect throttle return springs for proper tension, ensuring the throttle returns to idle position correctly. Replace any worn or damaged components promptly to avoid performance issues. Regular servicing prevents mechanical failures, ensuring reliable throttle response and safe boating experiences. Always refer to the manufacturer’s guidelines for specific maintenance recommendations tailored to the 4.5 HP Mercury outboard motor.

4.2 Adjusting the Throttle Linkage for Optimal Performance

Adjusting the throttle linkage ensures precise control and smooth operation. Start by loosening the adjustment nuts on the linkage rod, then move the throttle lever through its full range to ensure it moves freely without binding. Align the linkage to match the motor’s throttle cam, ensuring proper synchronization. Tighten the nuts securely after adjustments. Check the idle position by moving the throttle to the slowest setting and verifying the motor responds correctly. Fine-tune the linkage alignment if necessary to eliminate any mechanical resistance. Proper adjustment enhances fuel efficiency, reduces wear on components, and improves overall engine performance, ensuring reliable operation of the 4.5 HP Mercury outboard motor.

Troubleshooting Common Issues

Identify throttle linkage problems by checking for loose connections, worn parts, or misalignment. Refer to the diagram for locating components and diagnosing issues effectively.

5.1 Identifying and Diagnosing Problems

Common issues with the 4.5 HP Mercury outboard throttle linkage include hard starting, erratic engine behavior, or loss of throttle response. Use the diagram to locate components and trace connections. Inspect for worn or loose parts, such as cables or pivot points. Misalignment or corrosion in the linkage can disrupt proper function. Start by checking the throttle cable for frays or damage. Ensure all connections are secure and properly lubricated. Refer to the diagram to verify the correct routing and installation of components. If issues persist, consult the troubleshooting guide or seek professional assistance to avoid further damage. Regular inspection can prevent major repairs.

5.2 Repairing and Replacing Components

Repairing or replacing throttle linkage components requires careful attention to detail. Start by consulting the diagram to identify the problematic part. For example, a worn throttle cable or damaged pivot pin can be replaced by purchasing genuine Mercury parts. Use a torque wrench to ensure proper tightening of bolts and connections. Lubricate moving parts to maintain smooth operation. If the linkage is misaligned, adjust it according to the manufacturer’s specifications. For complex issues, refer to the service manual or consult a certified technician. Always follow safety guidelines to avoid further damage or injury. Regular maintenance can prevent costly repairs and extend the motor’s lifespan.

Safety Precautions and Best Practices

Always wear protective gear and ensure a clear, stable work area. Follow manufacturer guidelines for repairs and use appropriate tools to prevent damage. Regular inspection prevents issues.

6.1 Safety Guidelines for Handling the Throttle Linkage

Always disconnect the battery before servicing the throttle linkage to prevent accidental engine start-up. Wear protective gloves and eyewear to avoid injury from moving parts. Ensure the boat is on a stable, level surface and the motor is in neutral gear. Use proper tools to avoid damaging components. Never force parts into position, as this may lead to system failure. Follow the manufacturer’s manual for specific safety recommendations. Keep loose clothing and long hair tied back to prevent entanglement. Maintain a clean workspace to reduce the risk of slipping or tripping. Adhere to all safety guidelines to ensure safe and effective maintenance.

6.2 Best Practices for Long-Term Maintenance

Regularly lubricate the throttle linkage to prevent corrosion and wear. Clean the system thoroughly after use to remove dirt and grime. Store the motor in a dry, protected area during off-season to avoid rust. Always drain fuel before long-term storage to prevent degradation. Ensure proper alignment of the linkage during reinstallation for smooth operation. Refer to the manufacturer’s manual for specific maintenance schedules and recommendations. Use high-quality replacement parts to maintain system integrity. Perform routine inspections to identify and address potential issues early. By following these practices, you can ensure the throttle linkage remains reliable and efficient for years of trouble-free operation.

Additional Resources and References

Refer to MarineEngine.com for detailed parts diagrams and repair guides. Mercury’s official website offers technical manuals and troubleshooting resources for optimal maintenance and performance of your outboard motor.

7.1 Recommended Tools and Equipment

For servicing the 4.5 HP Mercury outboard motor, essential tools include a socket set, screwdrivers, pliers, and wrenches. A multimeter is useful for diagnosing electrical issues. A throttle linkage adjustment tool, available at marine hardware stores, ensures precise tuning. A service manual specific to the Mercury 4.5 HP model is crucial for guided repairs. Additionally, marine-grade lubricants and corrosion-resistant fasteners are recommended. Online retailers like MarineEngine.com offer genuine Mercury parts and accessories. Always use high-quality tools to maintain performance and longevity of the motor. Proper equipment ensures safe and effective maintenance, aligning with best practices for marine engine care.

7.2 Further Reading and Technical Documentation

For comprehensive understanding, refer to the official Mercury Marine website for detailed service manuals and parts diagrams specific to the 4.5 HP model. The Mercury Outboard Service Manual provides in-depth repair and maintenance guidance. Additionally, resources like MarineEngine.com offer extensive repair forums and downloadable PDF manuals. The Mercruiser Service Manual and Mercury Outboard Repair Manual are essential for advanced troubleshooting. Always consult genuine technical documentation for accurate throttle linkage diagrams and repair procedures. These resources ensure proper maintenance and compliance with manufacturer standards, helping to maintain optimal performance and extend the motor’s lifespan while adhering to safety and environmental guidelines.

The 4.5 HP Mercury outboard motor is a reliable choice for small watercraft, offering ease of operation and durability. Understanding the throttle linkage system is crucial for optimal performance and longevity. Regular maintenance, proper adjustments, and troubleshooting ensure smooth operation. Always refer to the official Mercury Marine documentation and diagrams for accurate repairs. By adhering to safety guidelines and manufacturer recommendations, users can maximize efficiency and safety while extending the motor’s lifespan. This guide provides a comprehensive overview, equipping users with the knowledge to maintain and troubleshoot their 4.5 HP Mercury outboard motor effectively, ensuring years of reliable service on the water.